Erect A Windmill

However, many properties in Australia still use windmills as the primary water supply for stock and people alike. The large mill seen to the left is in the Northern Territory of Australia. My 6-foot father is peering in, which is a measure of the size of this mill. Growing up on a sheep and cattle station, I was welding mill towers for the property by age ten.

Short Mill Story

I will tell a story about how my father fell off this tower. The fan spun at breakneck speed on a wild night with massive winds and thunderstorms crashing around. An anti-fouling lever pulls the fan out of the wind. It failed.

My father climbed up the tower to manually tie the tail out of the current, and as he was so doing, a tremendous bolt of lightning struck the tower, which threw him to the ground. Dad fell 10 metres (30 feet on the old scale) to the ground. Amazingly he didn’t break a bone and had just managed to tie the mill off. He survived the ordeal, bruised and battered. Back at work the next day. Imagine the OHS implications in today’s world!

Sizing a Mill

Apart from correctly locating the mill site, the critical dimensions affecting the performance are the fan’s diameter, the tower’s height and the pump size. The bigger the fan’s diameter, the more wind intercepted and, thus, the greater the power output by the mill. The higher the fan tower, the greater the wind speed intercepted and the lower the effect of ground turbulence, which reduces performance.

Planning an Erection

If you don’t appreciate and understand the above… then you shouldn’t erect a windmill! Never try and pitch a windmill by yourself. They can become unwieldy monsters, and at least two and preferably three people should assist. Talk over the various stages of erecting a windmill. Hence, each person knows the plan and what they should do at any given stage. A final rehearsal, talking and thinking through each action to erect a windmill tower, is a good idea.

Constructing the Mill

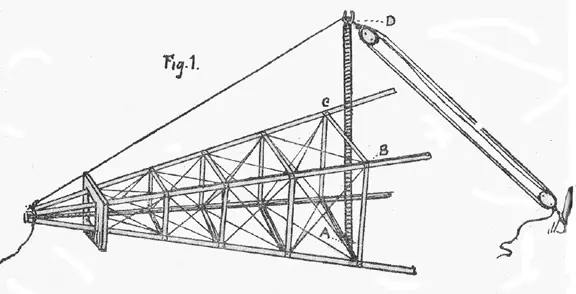

If you have purchased a windmill, the parts are marked. A new mill goes together without too much trouble. Two or three men can up-end a small tower of 20 feet. For larger, say 30-40 feet, a block and tackle can erect a windmill.

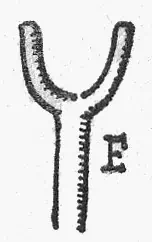

Into the end of the pipe (D) fits a part of the steel bar shaped as in Figure E. This allows the rope to pull directly from the top when the tower is about halfway up. If your rope is made fast at D, it is troublesome when about halfway up. To erect a windmill tower, have a loose rope fixed at the top on the opposite side of the pull to steady the tower if it moves in an unwanted fashion.

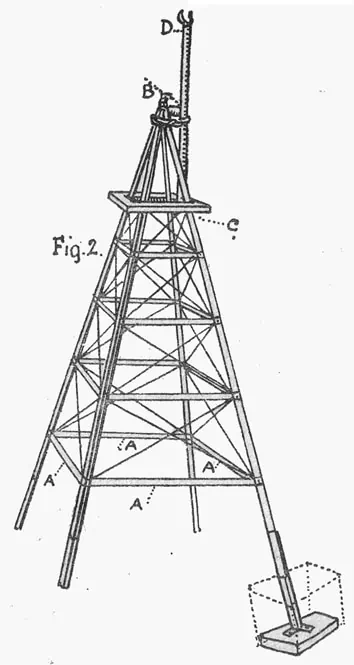

The holes should be deep enough to bury the leg within an inch or so of bolt holes A (Fig 3). Dig the holes and bolt the legs on. Wait to fill the holes with concrete. Tilt back the tower to allow the other legs to be sunk and fixed once all four (or three) legs are on. Use a spirit level to make them all accurate by levelling across the cross piece A (Fig 2). You can now pour concrete into the holes, tamping the slurry correctly and allowing it to cure before working further.

Putting on a head

In putting up the head and top gear, take the two-inch pipe and tie, as shown by putting a block of wood between the top of the mill and pipe (about six inches will do) at place B, tying securely to both sides of the tower at C. Do not pass ropes through the mill, and leave a clear passage for the top gear to come down.

Ensure you have enough pipe B to D length to allow room for blocks and top gear. A piece of steel rod shaped like Fig F is handy to go in at top D to put blocks on. You can put the tail up when the top gear is in place. When it is fixed, pull the tail out of the breeze and fix the wheel and sails. Some wheels can be assembled on the ground and pulled up. With others, it is easier to fit them straight to the head. Please be careful and plan carefully to erect your windmill tower.